Aircraft Fuel System Design: The Breakdown

We get it-you're not an aircraft mechanic. Your usual level of involvement with your aircraft’s fuel system may be the cringe you make as you pull out your wallet to finance yet another fill-up. Still, it doesn’t hurt for us to build our knowledge base and improve our ability to do some basic troubleshooting if something goes wrong.

Featured Pilot Gear

Browse our selection of high-quality pilot supplies! Your purchase directly supports our small business and helps us continue sharing valuable aviation content.

We get it-you're not an aircraft mechanic. Your usual level of involvement with your aircraft’s fuel system may be the cringe you make as you pull out your wallet to finance yet another fill-up.

Still, it doesn’t hurt for us to build our knowledge base and improve our ability to do some basic troubleshooting if something goes wrong. If that’s not enough incentive, here’s a little more—spend any amount of time around aircraft and you’ll hear or maybe even get suckered into a debate about the pros and cons of high wing vs low wing small general-aviation aircraft.

A couple of the perennial key points in the discussion involve the types of fuel systems and the location of the tanks. High tank or low tank? Gravity feed system vs fuel pump system? These are the questions that your fellow pilots will be debating.

The more you know about each type, the better prepared you will be to present your viewpoint and command the attention and respect of other, perhaps less well-versed pilots.

Ready to brush up on your fuel system knowledge? Let’s get started.

Table of Contents

Single Engine Aircraft Fuel Systems

The fuel systems of small, single engine GA aircraft are designed to suit their configuration and engine type. The two most common systems in these aircraft are gravity feed and fuel pump.

On some high-performance high-wing aircraft, you may see a fuel injection system rather than one of the carbureted systems.

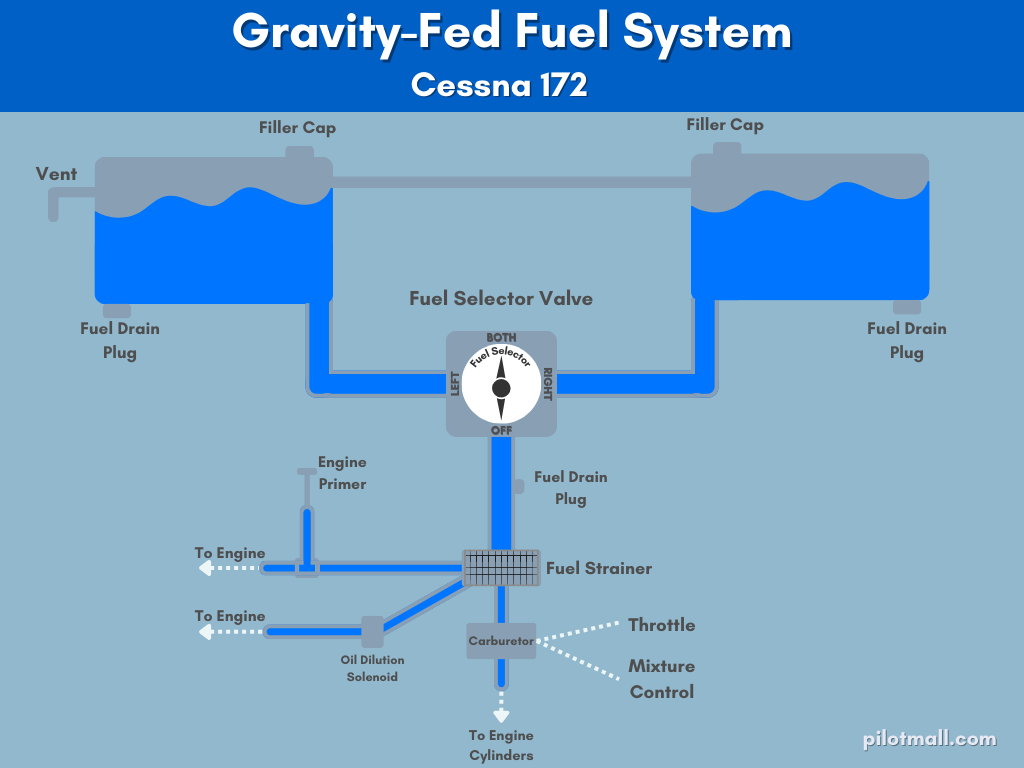

Gravity Feed System

Gravity Feed System

The gravity feed system is a type of aircraft fuel system found on single engine high wing aircraft. It is the simplest, most basic type of aircraft fuel system, and this is one of the reasons you will hear pilots advocate the high wing configuration. The downside is that refueling is a little more challenging thanks to high tank placement.

With a gravity feed system, you will have one or more likely two fuel tanks – one in each wing. Since the tanks are positioned higher than the engine, the fuel can feed down from the tank to the engine using gravity.

A tank vent facilitates pressure equalization inside each tank and the tanks also vent to each other, so they have the same pressure.

Once the fuel leaves the tank, it flows to the fuel selector valve. This valve allows the pilot to isolate each of the tanks so fuel flow can come from just the left tank, just the right tank, both tanks, or be shut off completely.

A downstream strainer removes any residual sediment and water before allowing the fuel to flow to the carburetor or primer pump in the engine.

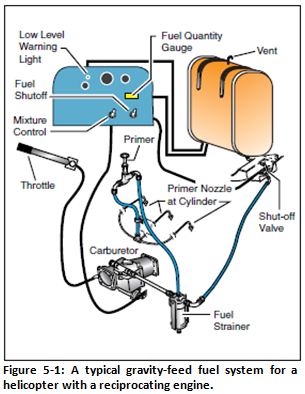

Fuel Pump System

(Pilot's Handbook of Aeronautical Knowledge (FAA-H-8083-25C), chapter 7, page 26)

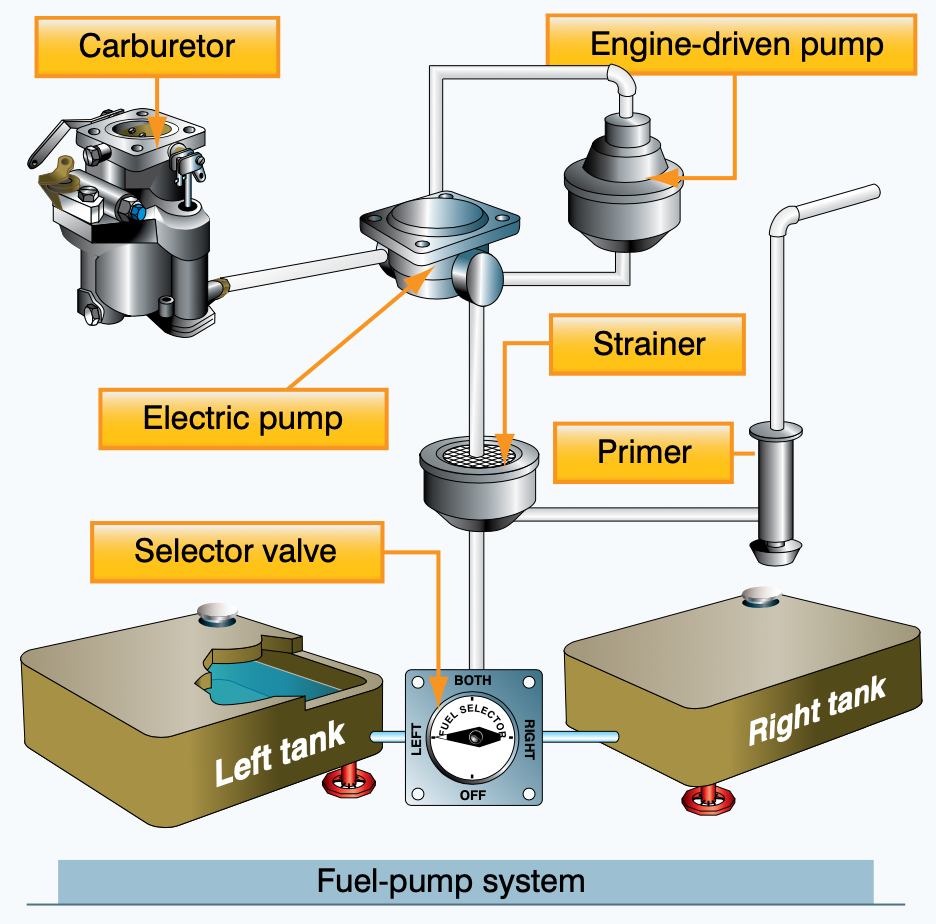

On low and mid-wing aircraft, you may not need a ladder for refueling, but you will be relying on a more complex fuel pump system to get the fuel from your tanks up to your engine.

In a fuel pump or pump feed system, the engine is positioned above the fuel tanks, and a pump/pumps draw the fuel from the tanks and deliver it to the engine. If the pump system fails, your engine will starve for fuel.

Unlike a gravity feed system, you may find that on your pump system, fuel cannot be drawn from both tanks at the same time. In this case, both the left and right tank run to a fuel selector valve that has just 3 positions: left, right and off.

Check your aircraft to confirm what options you have. Downstream of the selector is the strainer and engine primer, and then the fuel pumps.

For redundancy, most fuel pump systems use two pumps installed in a parallel configuration. The electric pump provides initial fuel pressure when starting the engine and serves as a backup to the primary engine-driven pump.

If the engine-driven pump fails, the electric pump can take over. During high altitude flights, the electric pump also works to prevent vapor lock.

Fuel Injection System

So far, both the systems we have reviewed have engines with carburetors, but not every single engine GA aircraft uses a carbureted engine.

Some high-performance models feature fuel injection systems instead. The fuel system on these aircraft is a combination of the two systems we already discussed. It uses both gravity flow and fuel pumps to feed pressurized fuel to the engine.

On a fuel injection system, fuel flows from the vented main fuel tanks down into individual fuel reservoir tanks which consolidate the fuel into an area with little airspace. After leaving the reservoir tanks, the fuel flows to a selector valve (often three-way with left, right and off functionality).

Auxiliary Fuel

An inline electric auxiliary fuel pump pulls the fuel from the selector valve and carries it through the strainer to supply both the primer pump and downstream engine-driven fuel pump.

The auxiliary fuel pump is primarily used for starting and serves as a backup to the primary engine-driven pump. If the auxiliary pump is turned off or isn’t working, the engine-driven pump can move the fuel from the selector valve through the strainer on its own.

Once pressurized fuel enters the engine-driven pump, the pump sends a high volume of the pressurized fuel to the fuel control unit. This unit meters the fuel based on engine RPM and the pilot’s mixture control inputs.

The fuel control unit then sends a metered amount of fuel to the distribution manifold and on to each cylinder’s fuel injectors in an equal and consistent flow. This consistent flow is key to the smooth operation of a fuel injection system.

After fuel has been sent to the injectors, any excess fuel and fuel vapors are returned to the reservoir tank via the pump.

The pilot can monitor the fuel flow thanks to a fuel flow indicator that gets its fuel pressure reading from the distribution manifold and translates that reading to gallons per hour.

Small Multi-Engine Aircraft Fuel Systems

As soon as you add a second engine to the mix, the fuel system naturally becomes more complex. Multi-engine systems need more fuel capacity, so they usually have two extra tanks.

Thankfully, many of the parts are still the same, so your baseline understanding of a single engine configuration will get you started on learning a reciprocating (multi-engine) system.

For purposes of building an entry-level understanding of these systems, we will break down the designs of basic high-wing twin and low-wing twin fuel system configurations.

High-Wing Twin System

High-Wing Twin System

On a high-wing twin, you are likely to see a combination system with gravity feed components as well as an electric fuel pump.

The location of fuel tanks can vary, but a basic high-wing twin engine fuel system often holds two tanks in each wing. The outboard tank on each side connects to the inboard tank which then runs to the selector valve.

The selector valves for both the left and right sets of tanks connect to allow the pilot to select where to pull the fuel from and which engine to direct it to.

Depending on your aircraft, you may or may not be able to select a crossfeed option which would send fuel from the tank/s on one side of your aircraft to the engine on the opposite side.

You may find that you need to crossfeed from one tank to the other first and then to the engine. Again, this will vary by aircraft, so learn your aircraft’s set-up.

Each set of tanks has its own stand-alone system downrange of the selector valve, so from that point on, you basically have two parallel individual systems – one for each engine.

For each engine, the fuel is pulled from the selector valve, through the strainer by an electric fuel pump which then sends pressurized fuel into the inlet on the fuel injection metering unit. This unit allocates and supplies the appropriate amount of fuel to the distribution manifold and individual fuel injection nozzles.

Low-Wing Twin System

Low-Wing Twin System

A basic low-wing twin fuel system also often contains two tanks on each side – a primary and an auxiliary. Since this system is larger than the single engine variation, to maintain system pressure and avoid vapor lock, you may find a boost pump near the outlet of each main tank.

The boost pump primes and starts the engine plus serves as the backup for the main engine-driven injection pump on each side.

At the selector valve for each engine, the pilot can choose where to pull the fuel from. Once the fuel source selection has been made, the fuel will pass through the strainer and into the engine fuel pump. Again, these are two systems working in parallel – one servicing each of the aircraft’s two engines.

In the fuel pump, a vapor separator will remove air along with any excess fluid and send it back toward the tanks. The remaining fuel will be pressurized and released to the fuel control.

Each engine’s fuel control regulates the fuel flow to the manifold and downstream injectors based on pilot entered mixture control settings and the aircraft’s RPM.

Jet Aircraft Fuel Systems

Jet Aircraft Fuel Systems

We’ve worked our way through the entry-level single engine GA aircraft fuel systems and leveled up to the intermediate twin engine configurations. Now, since we are not aircraft mechanics, we will just touch on the complex fuel systems found on jet aircraft.

The easiest way to keep from getting lost in the minutia of a jet engine fuel system is to break it down into subsystems. The first subsystem is storage. Large jet aircraft have hefty fuel needs, so we will have multiple fuel tanks in the wings and/or the fuselage.

The good news about all of these multiple tanks is that they are usually interconnected by a manifold, allowing for single point refueling from one location, usually under the wing or on the fuselage.

The second fuel subsystem on jets is venting. You will recall that our most basic single engine systems had a single vent on each fuel tank. Jets have a full interconnected vent system with float and check valves to ensure the tanks remain vented regardless of altitude.

The fuel distribution and feed subsystems are filled with backup safeties and redundancies to ensure that there is always a way to get fuel to the engines even if primary systems fail. For example, boost pumps in the tanks supply fuel to the engines.

They can also move fuel to the transfer manifolds and the transfer system is able to serve as a backup for distribution. If the boost pumps themselves aren’t working, a boost pump bypass maintains fuel flow.

The elaborate manifold system connects all the tanks and engines for increased redundancy and safety.

Speaking of safety, a jet’s fuel indicating system is robust and designed to keep the pilot continually apprised of the status of all aspects of the fuel system from fuel quantity to pressure to temperature.

Aviation Fuel Grades

Aviation Fuel Grades

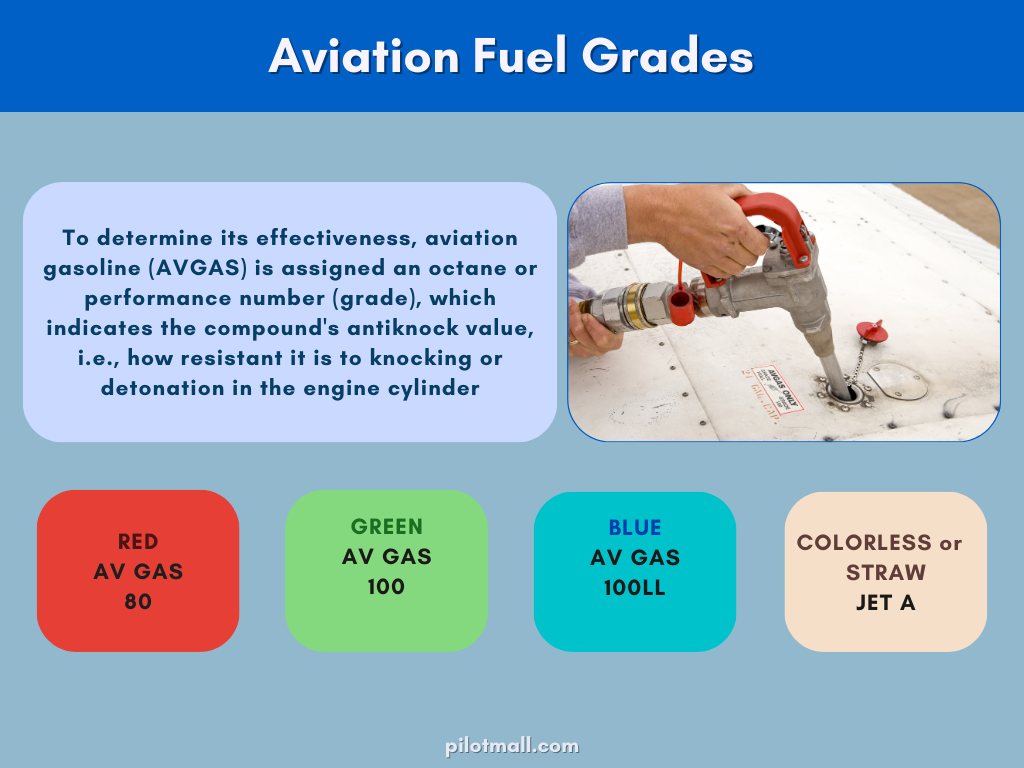

Aviation gasoline, also known as AVGAS can be identified by its octane or grade. The higher the grade the more the fuel can handle pressure without detonating.

AVGAS 100LL (LL stands for Low Lead) is the most commonly used aviation gasoline.

Takeaways

As pilots, we don’t need to be mechanics to understand the basics of how our aircraft’s fuel systems are designed. We can start by learning a simple single-engine gravity feed system and build from there.

Ultimately, a good working knowledge of our aircraft’s fuel system will help us to do initial troubleshooting if there is a problem and set us up for an intelligent conversation with the mechanic when we need to call in the experts.

Want to learn about different aircraft?

Our helpful guides provide everything you need to know!

Did you find this article helpful?

Do you think we missed anything important about aircraft fuel systems? Let us know in the comments below!